Submit feedback

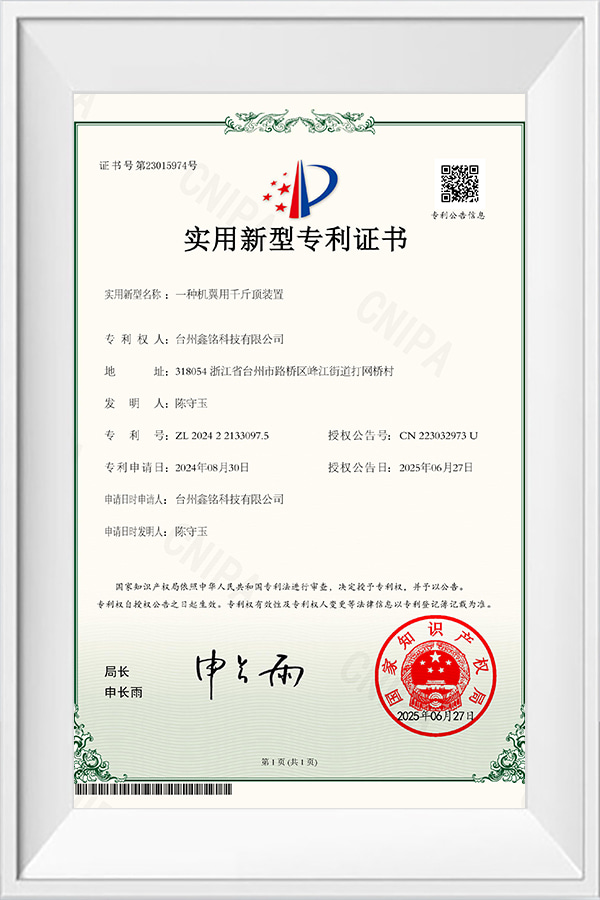

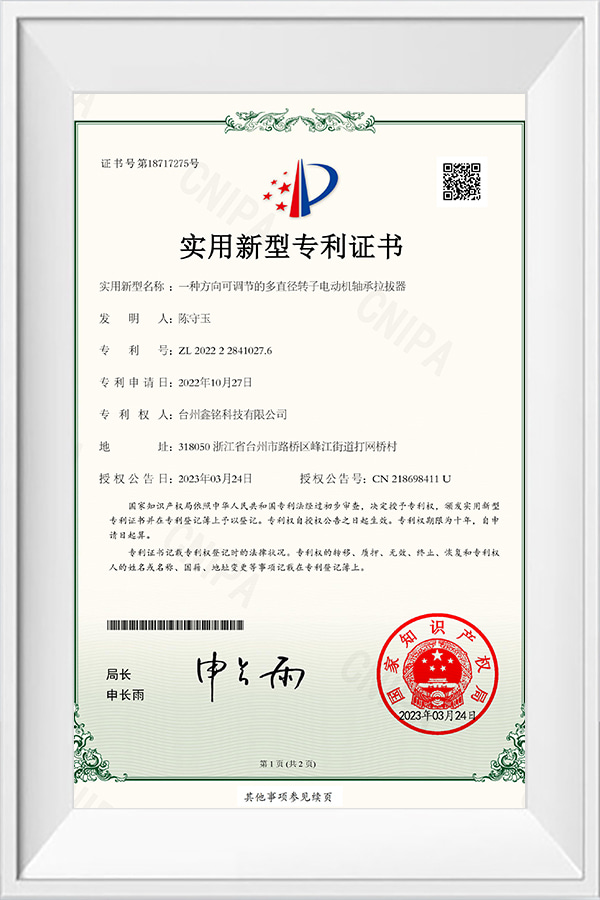

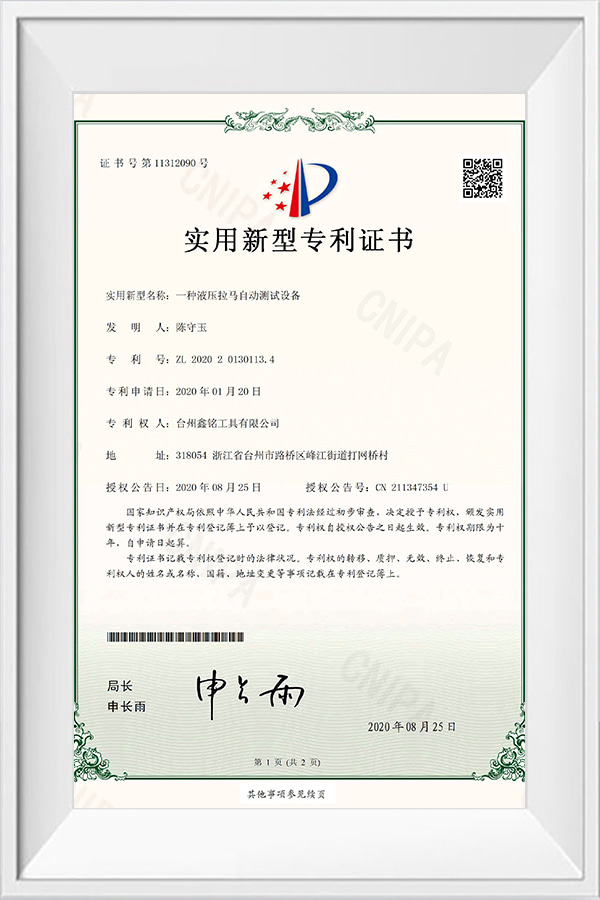

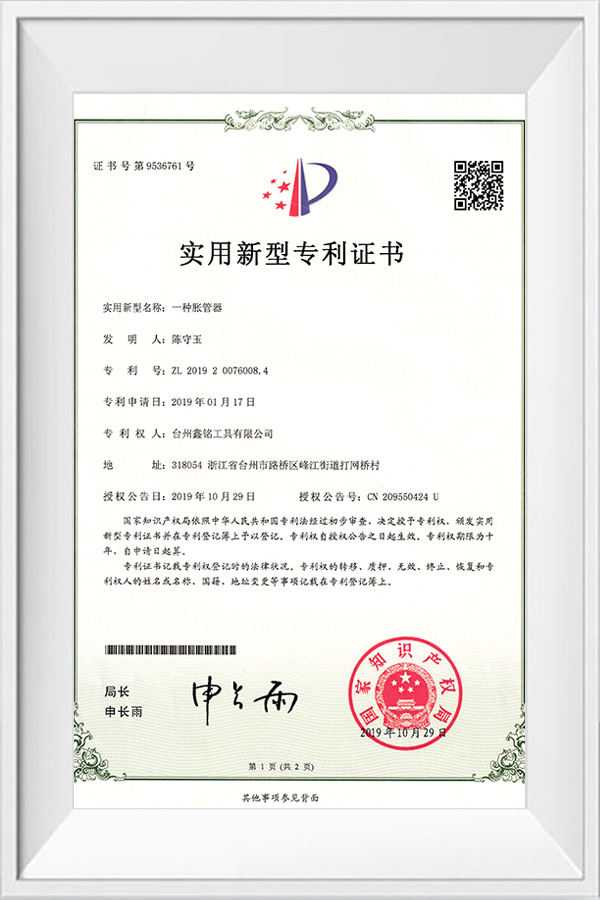

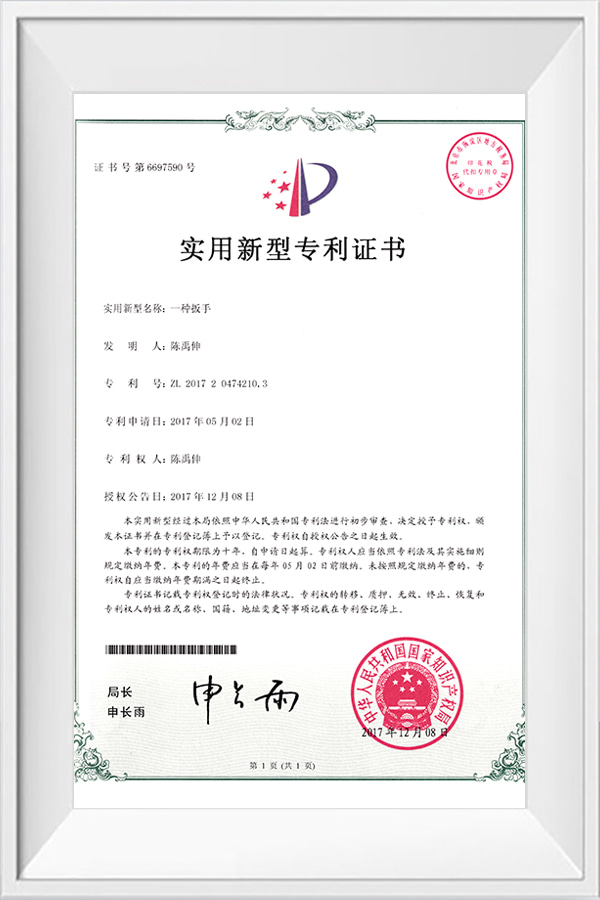

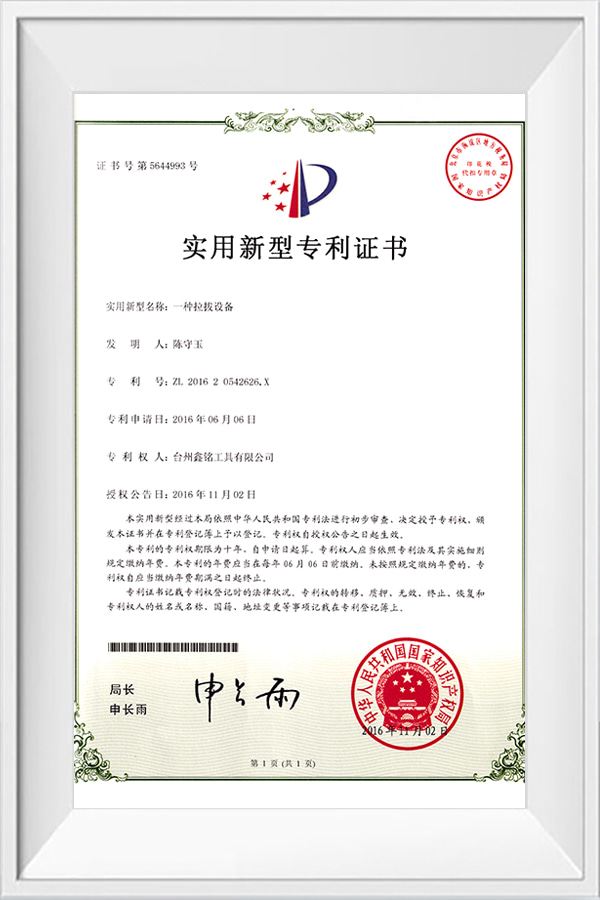

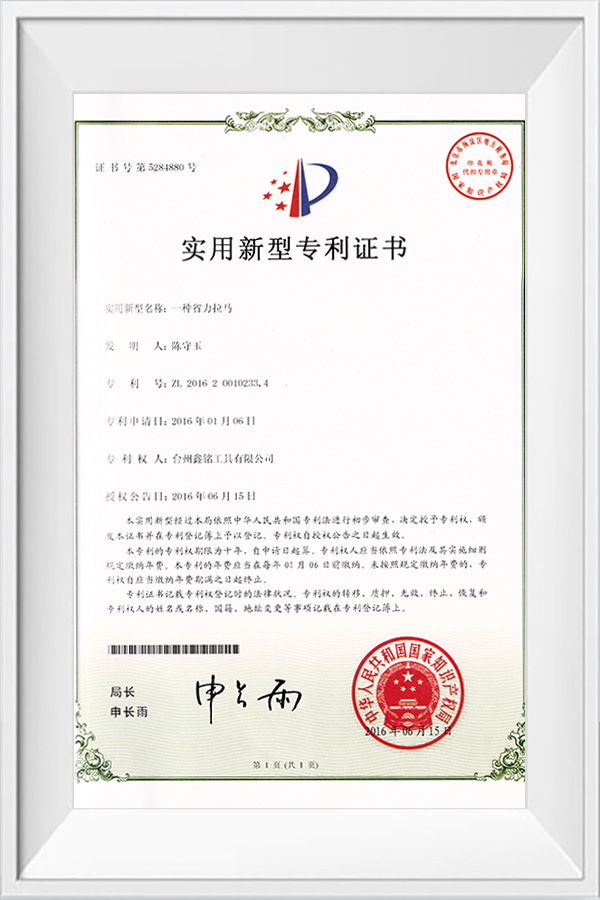

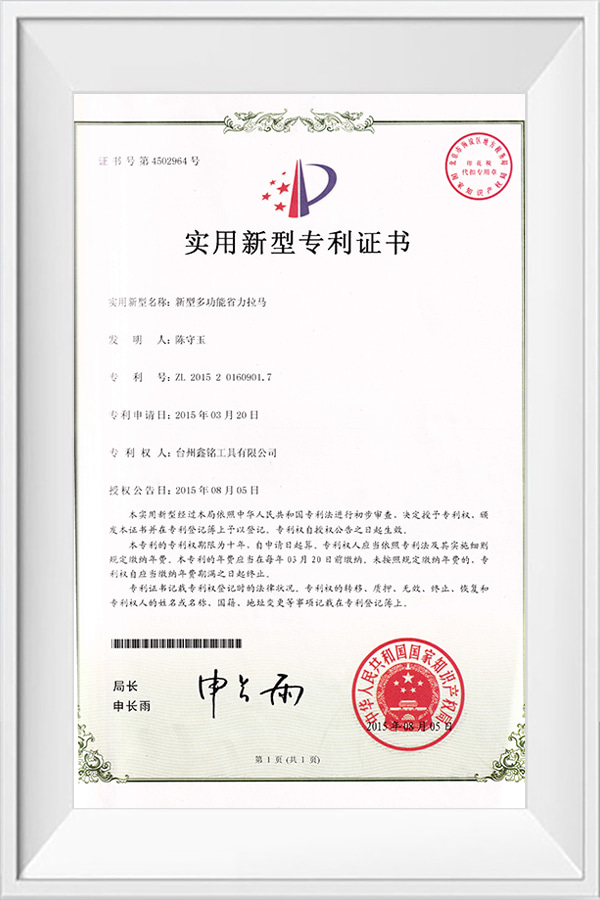

Taizhou Xinming Technology Co., Ltd. is a professional Hardware Tools manufacturer and OEM/ODM Automotive Maintenance Tools factory since 1995, specializing in pullers, automotive repair tools, hydraulic tools, and tool sets. As a participant in China's hardware standardization, we hold Zhejiang Manufacturing certification, ISO 9001:2015, and CE certifications. Our expert R&D team collaborates with top universities like Tianjin University to ensure premium quality through advanced technology and strict quality control. Committed to "Integrity and Excellence," we welcome global partners for long-term cooperation in advancing the hardware tools industry.

-

Jan 23, 2026Premium Materials for Long-Lasting Durability A Bearing Puller Maker emphasizes ...Read More

-

Jan 16, 2026High-Quality Materials for Strength and Longevity A Bearing Puller Producer emph...Read More

-

Jan 09, 2026Premium Materials for Strength and Durability A Gear Puller Manufacturing facili...Read More

-

Jan 02, 2026When it comes to mechanical repairs and maintenance, having the right tools is e...Read More

As a professional manufacturer of auto tools and mechanic tools, we frequently receive inquiries from workshops, distributors, and automotive enthusiasts about the applications, customization options, and safety measures for jaw pullers and other puller tools. From our factory perspective, these tools are essential components of any well-equipped garage.

1. What is a jaw puller used for in car repair?

A jaw puller is one of the most versatile puller tools in any automotive repair toolkit. It is specifically designed to remove tightly fitted components such as bearings, gears, pulleys, bushings, and even steering wheels without causing damage to the surrounding parts. In professional workshops and home garages alike, jaw pullers are considered essential auto tools. They help mechanics safely and efficiently extract components during engine overhauls, suspension maintenance, and brake system repairs. Using a high-quality jaw puller minimizes the risk of damage and reduces the time required for disassembly, making it a vital addition to any set of mechanic tools.

The puller tool allows for controlled force application, ensuring that even stubborn or rusted components can be removed without excessive strain. For auto repair shops that handle a variety of vehicles, a jaw puller is often paired with other auto tools to form a complete extraction system. Its versatility means it can be used in both light-duty tasks, such as replacing wheel bearings, and more heavy-duty operations, such as pulling off large pulleys or flywheels.

2. Can the puller jaws be customized in length or thickness?

Customization is a key feature we offer at our factory. Many customers ask, “Can the puller jaws be customized in length or thickness?” The answer is yes. By adjusting the jaw length, a jaw puller can reach deeply seated components in engines or suspension assemblies, which would otherwise be difficult to access. Increasing jaw thickness strengthens the puller tool, allowing it to withstand higher forces without bending or breaking.

These customizations ensure that our auto tools are suitable for a wide range of vehicles, from compact cars to SUVs and light trucks. Furthermore, customization extends the lifespan of the tool, making it reliable for both professional workshops and DIY mechanics. By providing adjustable options, our mechanic tools can meet specific client needs, ensuring safe and efficient removal of components in varied automotive repair scenarios.

3. Do you provide full-size ranges for different automotive repair needs?

Yes, our factory produces a full spectrum of jaw pullers and puller tools to accommodate different automotive repair requirements. We offer small, medium, and large sizes to meet the demands of compact vehicles, sedans, SUVs, and light trucks. This wide range ensures that all our auto tools can be integrated into a single toolkit for professional repair shops or modular sets for DIY enthusiasts.

The availability of full-size ranges means that mechanics can always select the correct puller tool for the job, improving efficiency and reducing the risk of component damage. Additionally, our mechanic tools are designed for compatibility with other auto tools, including wrenches, ratchets, and torque devices, enabling technicians to perform complex repairs with confidence. By providing a complete size range, we ensure that our customers have access to reliable, high-quality jaw pullers no matter the vehicle type or repair task.

4. How do you test the puller tool for durability and safety?

At our factory, durability and safety are top priorities. Each jaw puller and puller tool undergoes rigorous testing before leaving the production line. Material strength tests ensure that the steel used in our tools can withstand high torque and tension. Torque and load tests simulate real-world conditions, confirming that the auto tools will not bend, crack, or fail during use.

We also perform repeated extraction tests to verify the performance and reliability of each mechanic tool. This process ensures that every jaw puller can safely handle stubborn components, including rusted bearings and tightly pressed gears. Additionally, our puller tools are inspected for precision, ensuring uniform jaw alignment and smooth operation. By adhering to these strict quality control measures, our auto tools consistently meet international safety standards and provide long-lasting performance for automotive repair professionals.

From a factory perspective, jaw pullers and puller tools are fundamental auto tools for any automotive repair environment. They are highly versatile, customizable in length and thickness, available in full-size ranges for various vehicle types, and rigorously tested for durability and safety. Together with other mechanic tools, they allow technicians to perform repairs efficiently, safely, and reliably.

русский

русский Español

Español عربى

عربى