Submit feedback

Product

Gear Puller Maker

An auto gear puller is an automotive accessory designed to assist drivers in shifting gears without the need for manual clutch operation. This device is particularly useful for vehicles equipped with automatic transmission systems.

The auto gear puller connects to the transmission, allowing for seamless gear changes that enhance driving convenience and comfort. It works by engaging the transmission's internal mechanism to shift gears based on vehicle speed and throttle position automatically.

This puller is user-friendly, often featuring an ergonomic design for easy reach and operation. It's especially beneficial in traffic-heavy conditions where frequent gear changes are required, providing a smoother driving experience and reducing driver fatigue.

-

German Card Three-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Width(mm)

High(mm)

PCS

4″

110

110

10

6″

160

140

10

-

American Double-Hole Three-Jaw Puller

Size(inch)

Diameter(mm)

Capacity(ton)

PCS

1#

3 1/4″

2

20

2#

5 1/2″

5

20

3#

7″

7

10

4#

8 3/4″

9

5

-

5T Multifunctional Labor-Saving Puller

Capacity

5T

Length of Jaw

195mm

Cylinder stroke

80mm

Spread Ratio

1:16

Jaw Spread

75-200mm

-

10T Multifunctional Labor-Saving Puller

Capacity

1-5T/5-10T

Length of Jaw

265mm

Cylinder stroke

100mm

Spread Ratio

1:14/1:55

Jaw Spread

250-400mm

-

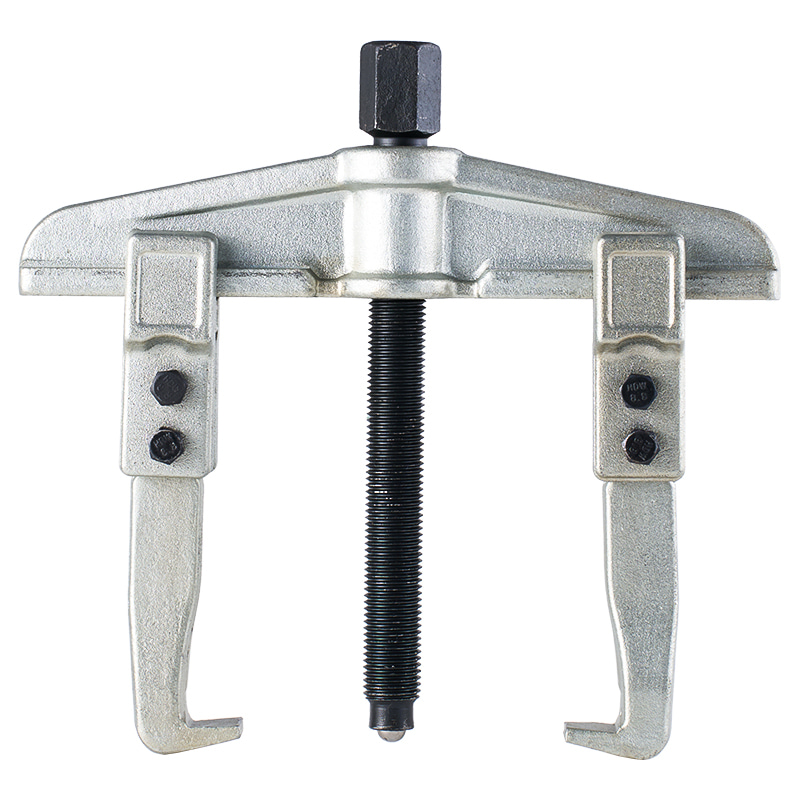

Single-Hole Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, light zinc■, yellow zinc■, chrome■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

14″

350mm

41*21*15

4

16″

400mm

45.5*14*19.5

2

-

Desktop Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, Matt chrome surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

-

Desktop High-End Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: chrome■, zinc■, matt surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

-

American Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, Matt chrome surface■

Size(inch)

Diameter(mm)

Capacity(ton)

PCS

1#

3 1/4"

2

20

2#

5 1/2”

5

20

3#

7"

7

10

4#

8 3/4”

9

5

-

German Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

G.W(kg)

3″

75mm

26*18.5*20.5

60

16/17

4″

100mm

35*15.5*19.5

40

20.2/21

6″

150mm

21.5*16.5*22

20

17/17.6

9″

200mm

26*18*26.5

10

21/21.6

12″

250mm

32.5*20.5*11.5

4

15.5/16

16″

300mm

37.5*12*22

4

20/21

-

High German Beam Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, matt surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

G.W(kg)

3″

90*100

38.5*31.5*14.5

16

14.6/15.6

4″

130*100

41*33.5*16.5

16

17.5/18.5

6″

160*150

38.5*28*29.5

12

32.5/33.5

8″

200*150

27.5*25*33.5

6

19.2/20

-

German Beam Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

G.W(kg)

A Max

Min B Max

3″

60

50-85

75

44*30*18

40

24.8/26

4″

85

50-105

85

34.5*30*25

26

21.6/22

6″

100

55-120

110

40.5*32.5*22.7

20

22.6/23.5

8″

130

55-150

140

36.5*23.5*31.5

16

23.2/24

10″

145

75-190

170

43.5*28.5*28

12

21/31.5

-

Beam Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, matt surface■

Size(inch)

Width(mm)

High(mm)

3″

110

105

4″

130

145

6″

160

185

8″

210

225

10″

270

225

12″

350

280

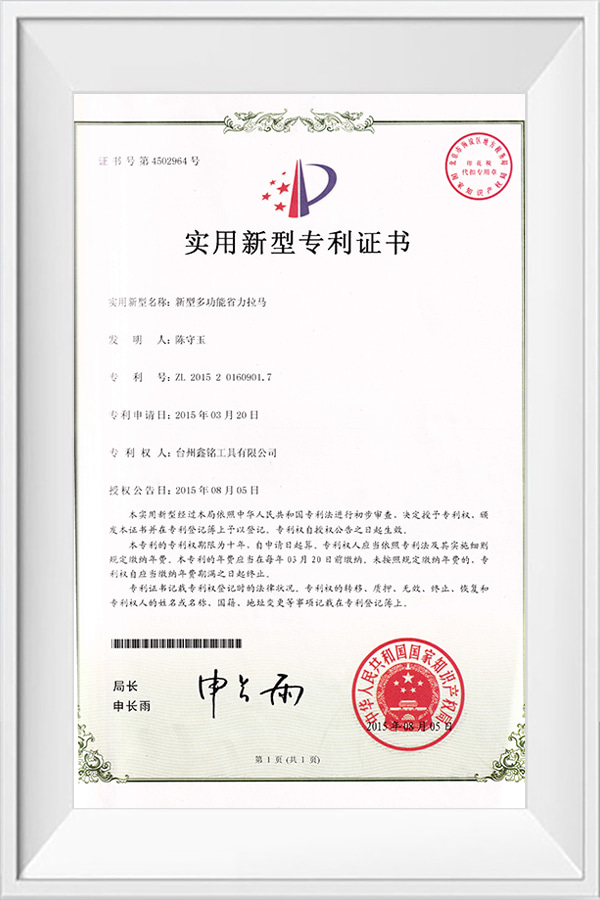

Taizhou Xinming Technology Co., Ltd. is a professional Auto Gear Puller manufacturer and OEM/ODM Auto Gear Puller factory since 1995, specializing in pullers, automotive repair tools, hydraulic tools, and tool sets. As a participant in China's hardware standardization, we hold Zhejiang Manufacturing certification, ISO 9001:2015, and CE certifications. Our expert R&D team collaborates with top universities like Tianjin University to ensure premium quality through advanced technology and strict quality control. Committed to "Integrity and Excellence," we welcome global partners for long-term cooperation in advancing the hardware tools industry.

-

Jan 23, 2026Premium Materials for Long-Lasting Durability A Bearing Puller Maker emphasizes ...Read More

-

Jan 16, 2026High-Quality Materials for Strength and Longevity A Bearing Puller Producer emph...Read More

-

Jan 09, 2026Premium Materials for Strength and Durability A Gear Puller Manufacturing facili...Read More

-

Jan 02, 2026When it comes to mechanical repairs and maintenance, having the right tools is e...Read More

As a professional Auto Gear Puller manufacturer, we frequently receive questions from workshops, distributors, and automotive enthusiasts about sizes, functionality, customization, and durability of our Gear Puller products. Below, we provide detailed answers from a factory perspective.

1. Do you offer different sizes or jaw lengths for auto gear pullers?

- Yes, our factory produces Auto Gear Pullers in a wide range of sizes and jaw lengths to meet diverse automotive repair needs.

- From small compact car applications to large trucks, our Gear Puller series covers multiple dimensions.

- Adjustable jaw lengths in Manual Puller Tools allow technicians to access deep-set gears, bearings, and pulleys without disassembling surrounding components.

- Offering different sizes ensures that each Auto Gear Puller fits the specific vehicle type, enhancing precision and reducing the risk of component damage.

- Custom sets of Multi-functional Pullers can be arranged to provide multiple jaw options in a single kit, improving versatility in workshops.

- By providing various sizes, our Gear Puller range ensures professional mechanics and DIY enthusiasts have the right tool for every extraction task.

2. Do your multi-functional pullers support both internal and external gripping?

- Absolutely. Our Multi-functional Puller line is designed to handle both internal and external gripping operations efficiently.

- Internal gripping allows the puller to extract components like bearings from inside housings, while external gripping targets gears, pulleys, or other outer components.

- Many of our Manual Puller Tools include adjustable arms and rotating bolts to switch between internal and external applications quickly.

- Technicians appreciate that a single Auto Gear Puller can perform multiple tasks, reducing the need for multiple dedicated tools.

- Each Gear Puller undergoes precision engineering to maintain jaw stability during both internal and external gripping.

- This multi-functionality makes our Multi-functional Pullers highly sought after in automotive workshops and industrial repair environments.

3. Can the puller arms be customized for heavy-duty industrial use?

- Yes, the arms of our Auto Gear Pullers can be reinforced or extended for heavy-duty industrial applications.

- By adjusting the thickness and material of the puller arms, our Gear Puller can withstand higher torque and load conditions without bending or breaking.

- Customized arms ensure that Manual Puller Tools remain safe and reliable, even in demanding environments.

- Our factory can produce heavy-duty Multi-functional Pullers for large machinery, trucks, or industrial gear systems.

- Reinforced arms improve durability and make the tool suitable for repeated, high-stress operations.

- This customization capability ensures that every Auto Gear Puller meets specific industrial requirements, providing both safety and efficiency.

4. What heat-treatment process is applied to improve jaw strength?

- All our Gear Pullers and Auto Gear Pullers undergo controlled heat-treatment processes to enhance jaw strength and durability.

- Typically, we apply quenching and tempering techniques to achieve optimal hardness while maintaining toughness.

- Heat treatment ensures that Manual Puller Tools resist deformation, cracking, or wear during repeated use.

- For Multi-functional Pullers, this process guarantees that both internal and external jaws maintain consistent gripping force over time.

- Surface finishing and stress-relief treatments are also applied to reduce fatigue and extend tool lifespan.

- As a result, our Auto Gear Puller products deliver reliable performance, even under heavy industrial or high-frequency automotive repair operations.

From a factory perspective, our Auto Gear Pullers, Gear Pullers, Multi-functional Pullers, and Manual Puller Tools are designed with precision, durability, and versatility in mind. We offer various sizes, adjustable jaws, and customized arms for heavy-duty use, while heat-treated jaws ensure safety and reliability. By combining functionality with robust engineering, our Auto Gear Pullers provide automotive and industrial technicians with high-quality tools that enhance efficiency and performance in every repair task.

русский

русский Español

Español عربى

عربى