Submit feedback

Product

Bearing Puller in China

An armature bearing puller is a specialized tool used in mechanical and automotive repair for the removal of bearings from their housings. It is designed to fit around the bearing, providing a secure grip and applying the necessary force to extract the bearing without causing damage.

The puller typically features an adjustable armature that can be set to match the size of the bearing, ensuring a firm hold. This tool is particularly useful when dealing with bearings that have been in place for a long time and have become difficult to remove due to rust or wear.

The armature bearing puller is operated manually, leveraging leverage to multiply the force applied by the user, making it an effective solution for removing bearings from tight spaces where access is limited. It is an essential tool for mechanics and technicians who perform regular maintenance and repair work, ensuring that bearings can be replaced efficiently and safely.

-

Mini Bearing Three-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: chrome■, zinc■

Size(inch)

High(mm)

Width(mm)

PCS

3″

40

60

50

4″

65

65

50

6″

80

80

50

-

Mini Bearing Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: chrome■, zinc■

Size(inch)

High(mm)

Width(mm)

3″

40

60

4″

65

65

6″

80

80

-

European Bearing Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: yellow zinc■, black■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

Measurement(cm)

PCS

Measurement(cm)

PCS

2″

35

45

45*25*21

50

50*32*24

80

36*20*20

100

3″

38

65

45*25*21

50

49.5*33*25

60

35*22*16

60

4″

40

85

36.5*28.5*23

40

41*33*25.5

40

35*25*16

50

6″

55

105

34.5*33.5*22.5

30

54*24*30

30

33*24*14

30

8″

70

130

41*25*24

20

42*27*30.5

20

33*19.5*16

25

-

Flat Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: chrome■, zinc■

Size(inch)

Width(mm)

High(mm)

2″

35

55

4″

65

80

6″

100

120

-

Bench Bearing Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: black■

Size(inch)

Width Min-Max(mm)

Measurement(cm)

PCS

G.W(kg)

AB-1

19-35

33.5*27*25

40

11.3/13.1

AB-2

24-55

44.5*23.5*29

24

16.3/18.4

AB-3

35-80

30.5*30*36

12

19.6/20.5

-

Inner Hole Bearing Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: black■

Size(inch)

Diameter (mm)

Measurement(cm)

PCS

G.W(kg)

2″

12-58

39.5*27.5*29.5

20

16.4/17

-

Bearing Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: black■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

G.W(kg)

3″

85

70

37*31*31

1

0.42

-

Spiral Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: black■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

G.W(kg)

1

2

3

1-160

2-135

3-65

80

31*25*24

40

19.5

X 01

01-70

60

-

Timing Belt Pulley Removal Puller

Crankshaft timing gear puller

Used to remove the Crankshaft timing gear working ability: 40-90mm, suitable for different model length of jaw: 100mm

-

Single-Sided Two-Jaw Puller

-

German Cassette Two-Jaw Puller

Size(inch)

Width(mm)

High(mm)

4″

110

110

6″

160

140

-

Water Pump Stator Puller

Size: 370-550w 550-750w

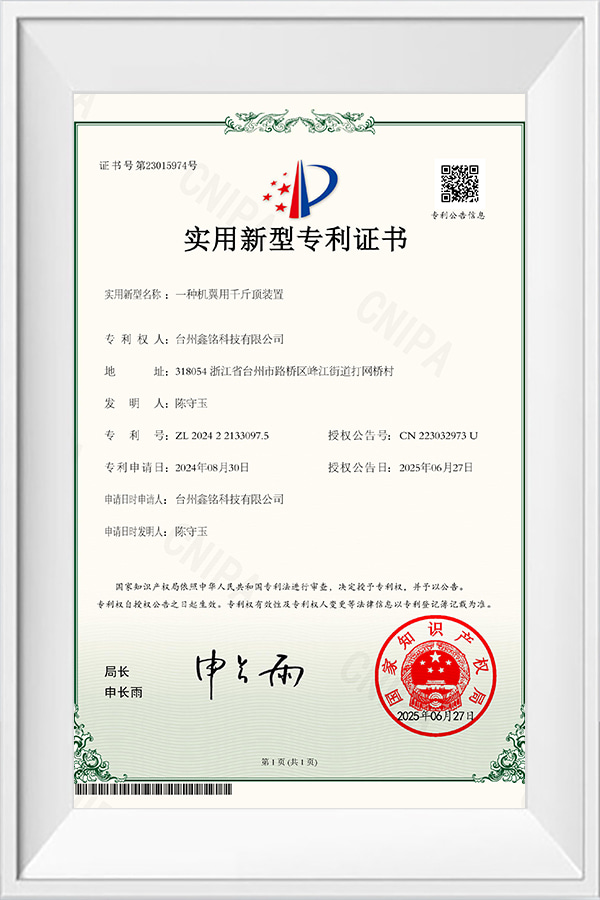

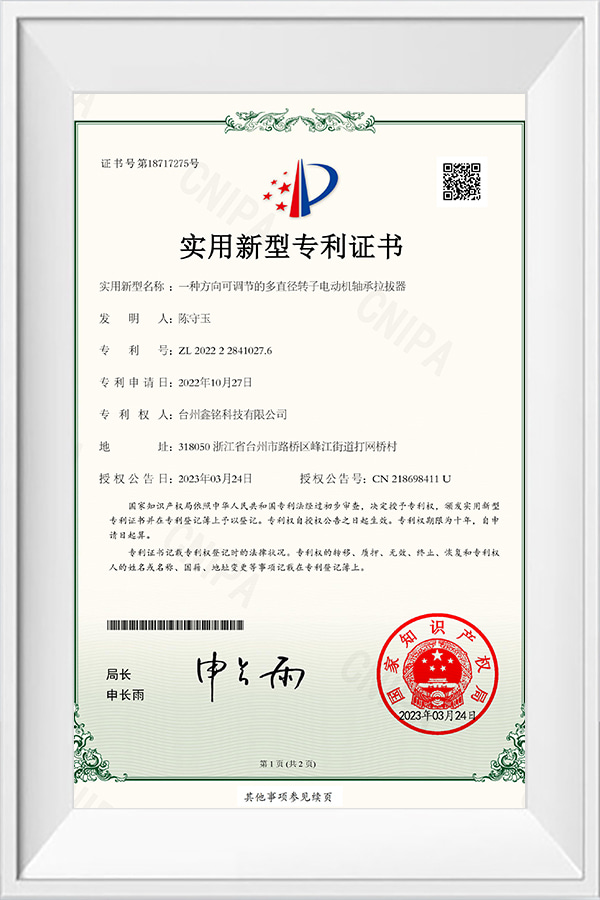

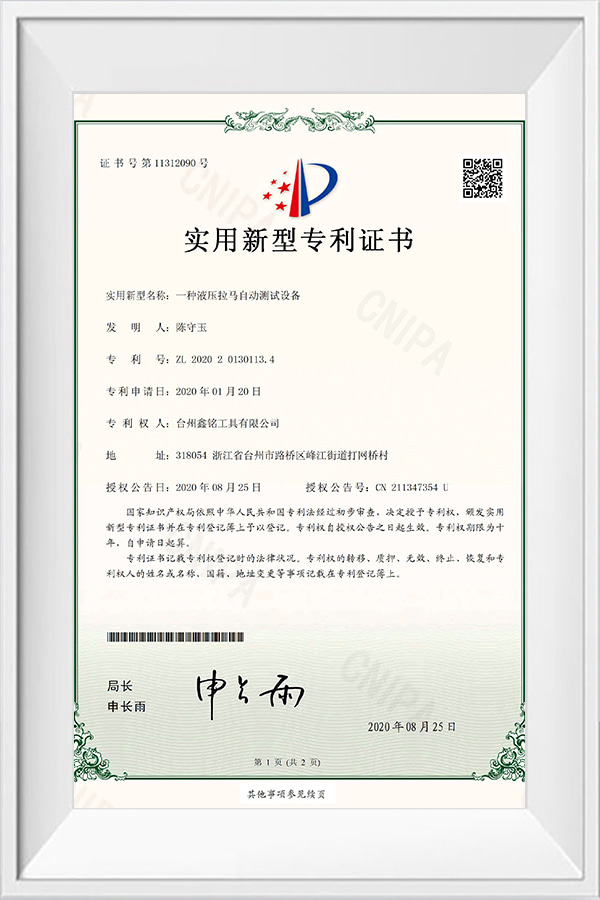

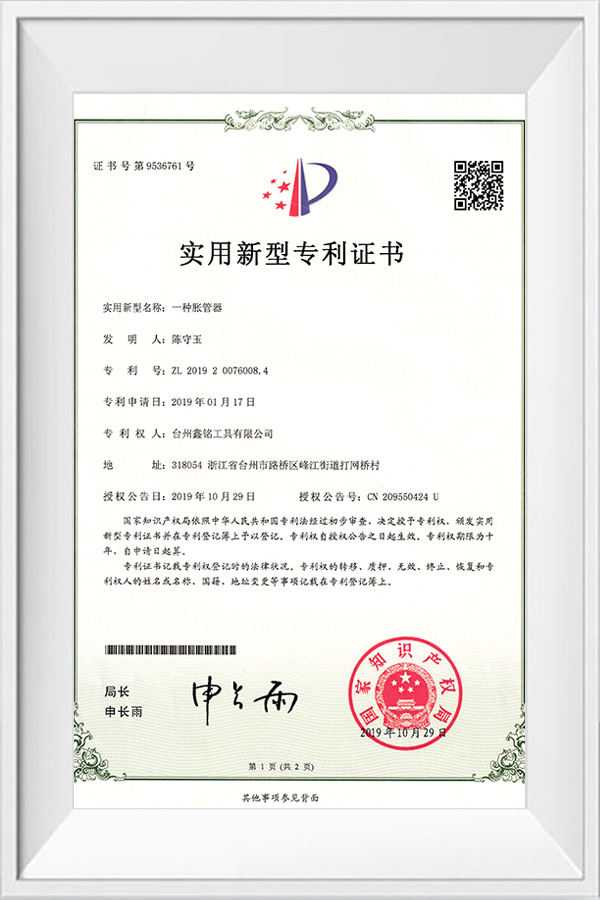

Taizhou Xinming Technology Co., Ltd. is a professional Armature Bearing Puller manufacturer and OEM/ODM Armature Bearing Puller factory since 1995, specializing in pullers, automotive repair tools, hydraulic tools, and tool sets. As a participant in China's hardware standardization, we hold Zhejiang Manufacturing certification, ISO 9001:2015, and CE certifications. Our expert R&D team collaborates with top universities like Tianjin University to ensure premium quality through advanced technology and strict quality control. Committed to "Integrity and Excellence," we welcome global partners for long-term cooperation in advancing the hardware tools industry.

-

Jan 23, 2026Premium Materials for Long-Lasting Durability A Bearing Puller Maker emphasizes ...Read More

-

Jan 16, 2026High-Quality Materials for Strength and Longevity A Bearing Puller Producer emph...Read More

-

Jan 09, 2026Premium Materials for Strength and Durability A Gear Puller Manufacturing facili...Read More

-

Jan 02, 2026When it comes to mechanical repairs and maintenance, having the right tools is e...Read More

As a professional Armature Bearing Puller manufacturer, we specialize in designing high-quality wheel bearing removal tools and adjustable bearing puller tools that combine durability, precision, and versatility.

From small electric motor bearings to larger automotive applications, our Armature Bearing Pullers provide reliable solutions for both professional and DIY workshops, helping technicians perform safe and efficient component extractions.

1. What's the difference between a bearing splitter and a puller tool?

A bearing puller tool is specifically designed to extract bearings, gears, and pulleys by applying controlled force. It works by gripping the component and allowing technicians to pull it off its shaft or housing. In contrast, a bearing splitter, sometimes called a separator, is used to safely separate tightly fitted bearings from their housings before extraction.

Our Armature Bearing Puller sets often include both components. Using a bearing puller tool without a splitter on press-fitted bearings can risk cracking or damaging the housing. By combining a bearing splitter with a wheel bearing removal tool, the process becomes safer and more efficient. This distinction ensures that workshops can maintain precision and protect both components and tools while performing extractions with our bearing puller tools.

2. What range of bearing sizes can your armature bearing puller support?

Our Armature Bearing Puller products are designed to cover a wide range of bearing diameters. From small electric motor bearings to medium automotive wheel bearings, our bearing puller tool line accommodates diameters from approximately 10mm to over 120mm.

The wheel bearing removal tool series is optimized for automotive applications, allowing mechanics to handle both standard car bearings and larger industrial components. Adjustable jaws in our bearing puller tools make it easy to switch between different sizes without requiring multiple pullers. Every Armature Bearing Puller is tested for reliability and consistency across the full size range, ensuring smooth operation in varied workshop environments.

3. Are adjustable bearing pullers better for mixed workshop use?

Yes, adjustable bearing puller tools provide excellent versatility. Our Armature Bearing Puller designs feature flexible arms and adjustable jaws that allow both internal and external pulling operations.

This adaptability makes them suitable for mixed-use workshops, where technicians may encounter bearings of various sizes and fits. A wheel bearing removal tool with adjustable jaws can handle everything from small electric motor bearings to large automotive components. By investing in adjustable bearing puller tools, workshops reduce the need for multiple specialized pullers while maintaining safety and efficiency. Each Armature Bearing Puller is engineered to ensure durability and consistent performance in different scenarios.

4. How do I avoid cracking the housing when using a bearing puller tool?

Preventing housing damage is critical when using a bearing puller tool. Our factory recommends always aligning the jaws properly on the component before applying pressure. For larger bearings, using a wheel bearing removal tool with a built-in separator can significantly reduce stress on the housing.

Lubricating contact points or using adapters for uneven surfaces further minimizes the risk of cracking. High-quality bearing puller tools manufactured from hardened steel ensure even force distribution. By following these best practices, every Armature Bearing Puller can safely remove bearings while protecting both the housing and surrounding components, making the extraction process efficient and reliable.

Reliable Bearing Pullers for Every Workshop

From a factory perspective, Armature Bearing Pullers and bearing puller tools are essential for safe, efficient, and versatile bearing extraction.

Understanding the difference between a bearing splitter and a puller tool, choosing the correct size range, using adjustable pullers for mixed workshop use, and following proper operational techniques all contribute to safe and reliable repairs.

Our wheel bearing removal tool and bearing puller tool lines are engineered with durability, precision, and adaptability in mind. By combining quality materials, adjustable jaws, and robust construction, our Armature Bearing Pullers ensure that workshops and technicians can handle diverse bearing removal tasks with confidence and safety.

русский

русский Español

Español عربى

عربى