Submit feedback

Product

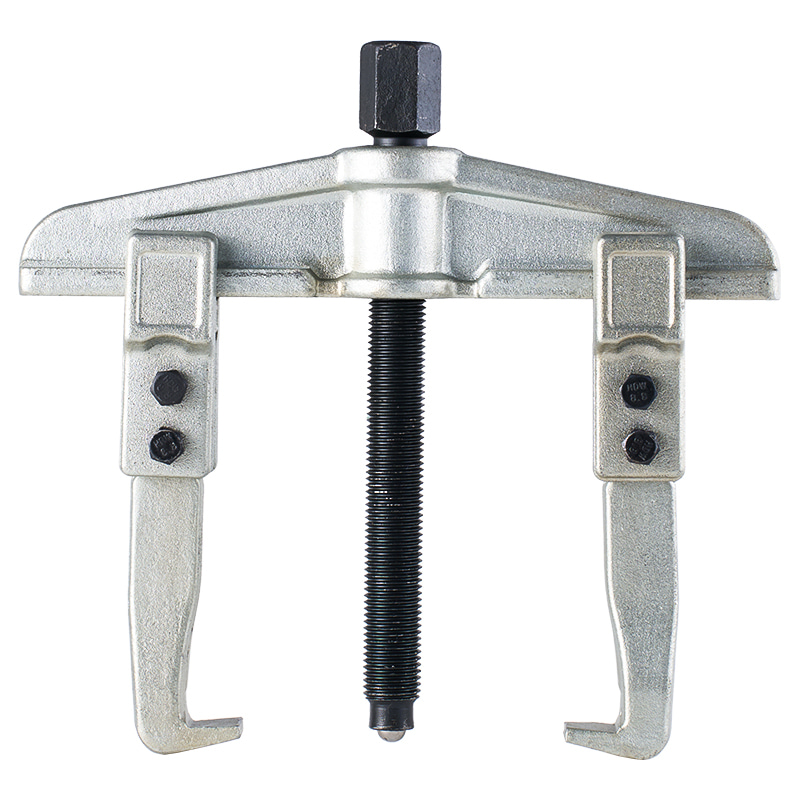

Two Jaw Gear Puller Factory

A two-jaw gear puller is a mechanical tool used for removing gears, bearings, and other components from shafts. It features two adjustable jaws that can be set to fit various sizes, ensuring a secure grip on the part being removed.

The puller applies even force, reducing the risk of damaging the component. Typically operated by a hydraulic or pneumatic system, it provides the necessary force to extract stubborn parts.

The two-jaw design allows for precise positioning and is particularly useful for tasks requiring careful removal of components without causing additional damage. This tool is an essential piece of equipment in automotive repair and industrial maintenance settings where precision and power are crucial.

-

Single-Hole Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, light zinc■, yellow zinc■, chrome■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

14″

350mm

41*21*15

4

16″

400mm

45.5*14*19.5

2

-

Desktop Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, Matt chrome surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

-

Desktop High-End Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: chrome■, zinc■, matt surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

3″

75mm

26*18.5*20.5

40

4″

100mm

35*15.5*19.5

25

6″

150mm

21.5*16.5*22

10

8″

200mm

26*18*26.5

10

10″

250mm

32.5*20.5*11.5

4

12″

300mm

37.5*12*22

4

-

American Double-Hole Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, Matt chrome surface■

Size(inch)

Diameter(mm)

Capacity(ton)

PCS

1#

3 1/4"

2

20

2#

5 1/2”

5

20

3#

7"

7

10

4#

8 3/4”

9

5

-

German Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

G.W(kg)

3″

75mm

26*18.5*20.5

60

16/17

4″

100mm

35*15.5*19.5

40

20.2/21

6″

150mm

21.5*16.5*22

20

17/17.6

9″

200mm

26*18*26.5

10

21/21.6

12″

250mm

32.5*20.5*11.5

4

15.5/16

16″

300mm

37.5*12*22

4

20/21

-

High German Beam Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, matt surface■

Size(inch)

Diameter(mm)

Measurement(cm)

PCS

G.W(kg)

3″

90*100

38.5*31.5*14.5

16

14.6/15.6

4″

130*100

41*33.5*16.5

16

17.5/18.5

6″

160*150

38.5*28*29.5

12

32.5/33.5

8″

200*150

27.5*25*33.5

6

19.2/20

-

German Beam Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

G.W(kg)

A Max

Min B Max

3″

60

50-85

75

44*30*18

40

24.8/26

4″

85

50-105

85

34.5*30*25

26

21.6/22

6″

100

55-120

110

40.5*32.5*22.7

20

22.6/23.5

8″

130

55-150

140

36.5*23.5*31.5

16

23.2/24

10″

145

75-190

170

43.5*28.5*28

12

21/31.5

-

Beam Two-Jaw Puller

Material: 40#CRV

The production process: drop-forged

Available Surface treatment: zinc■, chrome■, matt surface■

Size(inch)

Width(mm)

High(mm)

3″

110

105

4″

130

145

6″

160

185

8″

210

225

10″

270

225

12″

350

280

-

American Beam Two-Jaw Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: chrome■, zinc■

Size(inch)

Width(mm)

High(mm)

Measurement(cm)

PCS

G.W(kg)

3″

100

90

44*30*18

40

20.5/21

4″

120

110

34.5*30*25

26

19/19.8

6″

140

125

40.5*32.5*22.7

20

17.6/18.5

8″

170

165

36.5*23.5*31.5

16

20/21

10″

200

205

43.5*28.5*28

12

27/28

-

Two-Jaw Universal Puller

Material: 45#SC

The production process: drop-forged

Available Surface treatment: zinc■, chrome■

Size(inch)

Width(mm)

High(mm)

1#

175

120

2#

175

235

3#

175

280

4#

260

175

5#

260

320

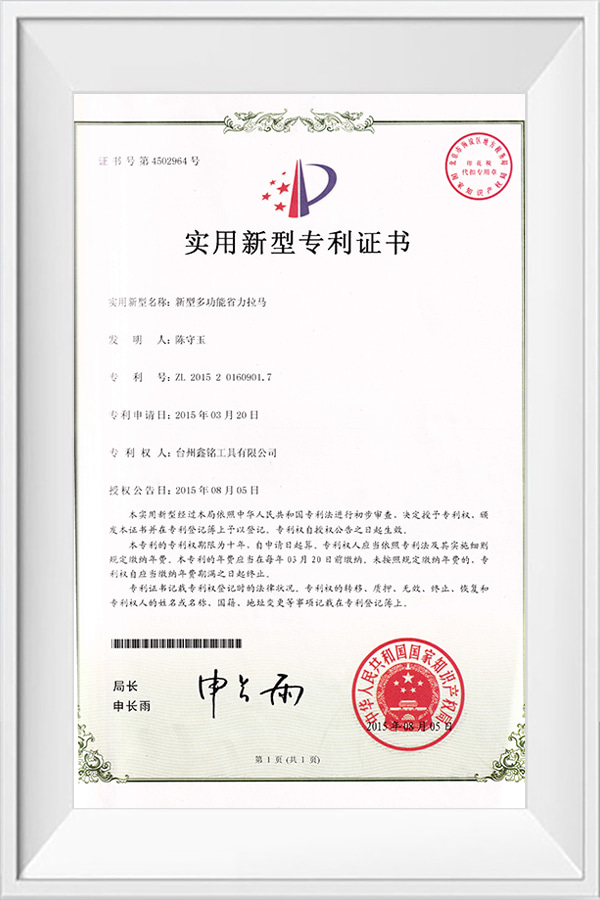

Taizhou Xinming Technology Co., Ltd. is a professional Two Jaw Gear Puller manufacturer and OEM/ODM Two Jaw Gear Puller factory since 1995, specializing in pullers, automotive repair tools, hydraulic tools, and tool sets. As a participant in China's hardware standardization, we hold Zhejiang Manufacturing certification, ISO 9001:2015, and CE certifications. Our expert R&D team collaborates with top universities like Tianjin University to ensure premium quality through advanced technology and strict quality control. Committed to "Integrity and Excellence," we welcome global partners for long-term cooperation in advancing the hardware tools industry.

-

Jan 23, 2026Premium Materials for Long-Lasting Durability A Bearing Puller Maker emphasizes ...Read More

-

Jan 16, 2026High-Quality Materials for Strength and Longevity A Bearing Puller Producer emph...Read More

-

Jan 09, 2026Premium Materials for Strength and Durability A Gear Puller Manufacturing facili...Read More

-

Jan 02, 2026When it comes to mechanical repairs and maintenance, having the right tools is e...Read More

As a leading Two Jaw Gear Puller manufacturer, we frequently receive questions from automotive workshops, distributors, and home mechanics about the applications, advantages, and limitations of two jaw pullers compared to Three Jaw Gear Pullers.

Our factory specializes in designing and producing reliable two arm gear pullers and 2 jaw puller sets that meet both professional and DIY requirements. From compact car repairs to delicate bearing removal, these tools are engineered to provide precision, durability, and ease of use in various automotive scenarios.

1. When should I use a two jaw gear puller instead of a three jaw puller?

- A two jaw puller is ideal for situations where access to the component is limited or where the part is asymmetrical.

- Compared to a Three Jaw Gear Puller, a two arm gear puller provides easier positioning in tight spaces and is often lighter for manual use.

- Our Two Jaw Gear Puller line is designed for automotive pulleys, small bearings, and bushings where balanced extraction from three points is not required.

- While a 3 jaw puller distributes force evenly, a two jaw puller can still safely remove components when proper alignment and caution are applied.

- Technicians often choose a two arm gear puller for tasks where a compact, adjustable puller is more practical than a full Three Jaw Gear Puller.

- Our 2 jaw puller set includes various sizes, making it easy to select the right tool for each job without compromising safety.

2. Is a two arm gear puller safe to use on delicate bearings?

- Yes, when used correctly, a two arm gear puller is safe for delicate or precision bearings.

- Our factory designs two jaw puller jaws with smooth, high-strength surfaces to minimize damage to soft metals and sensitive components.

- Proper jaw alignment and gradual pressure application are essential to prevent scratches or deformation.

- While a Three Jaw Gear Puller may offer more stability, a two arm gear puller is preferred for smaller, delicate parts because it is easier to handle and control.

- All our 2 jaw puller set tools undergo rigorous material and durability testing to ensure consistent performance.

- Using a two jaw puller alongside proper safety protocols ensures efficient removal of delicate automotive bearings and bushings.

3. How do I prevent slipping when using a 2 jaw puller?

- Slippage can be minimized by ensuring the jaws of the two jaw puller are properly seated on the component before applying pressure.

- Our Two Jaw Gear Puller models are designed with adjustable jaw tips to conform to various part shapes.

- Using a light lubricant or anti-slip coating on the jaws can also improve grip, especially on oily or worn surfaces.

- Avoid uneven pressure by turning the center bolt steadily, ensuring the two arm gear puller remains aligned.

- Compared to a Three Jaw Gear Puller, which naturally distributes force, the two jaw puller requires a bit more care, but our 2 jaw puller set design minimizes the risk of accidental slippage.

- Proper training and the correct tool size from our 2 jaw puller set ensure a safer and more controlled extraction process.

4. Is a compact 2 jaw puller better for home DIY use?

- Yes, compact two jaw pullers are ideal for home garages and DIY enthusiasts.

- They are lighter, easier to store, and capable of handling most small automotive repairs without requiring extensive workshop equipment.

- Our Two Jaw Gear Puller models are designed for versatility, allowing a single tool to handle multiple pulley and bearing sizes.

- While a Three Jaw Gear Puller may be preferred in professional shops for heavier-duty tasks, the compact two jaw puller is more practical for occasional DIY work.

- The 2 jaw puller set provides a range of sizes suitable for home projects, combining portability with reliable performance.

- For DIY mechanics, having a two arm gear puller ensures efficient, safe repairs without investing in a full Three Jaw Gear Puller toolkit.

Our Two Jaw Gear Pullers, two arm gear pullers, and 2 jaw puller sets are designed to deliver safe, efficient, and versatile solutions for automotive repairs. While Three Jaw Gear Pullers excel in heavy-duty applications, the two jaw puller is ideal for tight spaces, smaller components, and home DIY projects.

Every tool we manufacture undergoes strict quality control to ensure longevity and consistent performance. By combining portability, precision, and reliability, our two jaw pullers offer mechanics and DIY enthusiasts a practical and indispensable addition to their auto tools and workshop kits.

русский

русский Español

Español عربى

عربى